Current Flow around Defect Structures

R. Yongsunthon, A. Stanishevsky and E.D. Williams

Materials Research Science and Engineering Center

University of Maryland, College Park

Philip Rous

Department of Physics

University of Maryland, Baltimore County

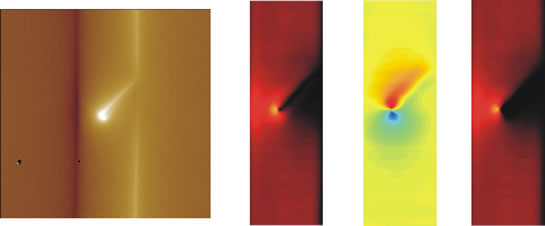

The metal in electrical wires can actually

be displaced by the flow of electrical current through the wires. This

electromigration-effect is the principle cause of failure in interconnects,

and may dominate the behavior of future nano-scale devices. Mass flow

under electromigration is influenced by the tendency of electrical current

to “bunch” in the region of corners, bends, cracks or materials

defects at the sub-micron size. We have made the first direct observation

of current crowding by exploiting the high spatial resolution available

using magnetic force microscopy. The MFM signature of a fabricated model

defect is shown in the Figure, with the current density obtained by inverting

the image. Away from the defect, the current density is uniform, but the

current deflected around the defect clearly concentrates at the end of

the structure, and there are current “shadows” around the

edges of the defect. Imaging current distributions in this way will allow

hidden defects to be discovered and characterized, and device characteristics

to be quantified in the presence of nanoscale features.

Figure: Left panel - MFM image of 10 micron wide, 0.1 micron thick Au

line, with FIB-fabricated diagonal slit-defect. Current applied is 33

mA. Remaining panels: current density determined by deconvolving the instrumental

broadening and then performing a numerical inversion using the Biot-Savart

Law. The component of the current parallel to line edges is shown in the

second panel, the component perpendicular to the edges in the third panel,

and the net current in the final panel. The decrease of current density

in the “shadow” of the slit is striking, as well as the four-fold

increase in current density within one micron of the end of the defect.